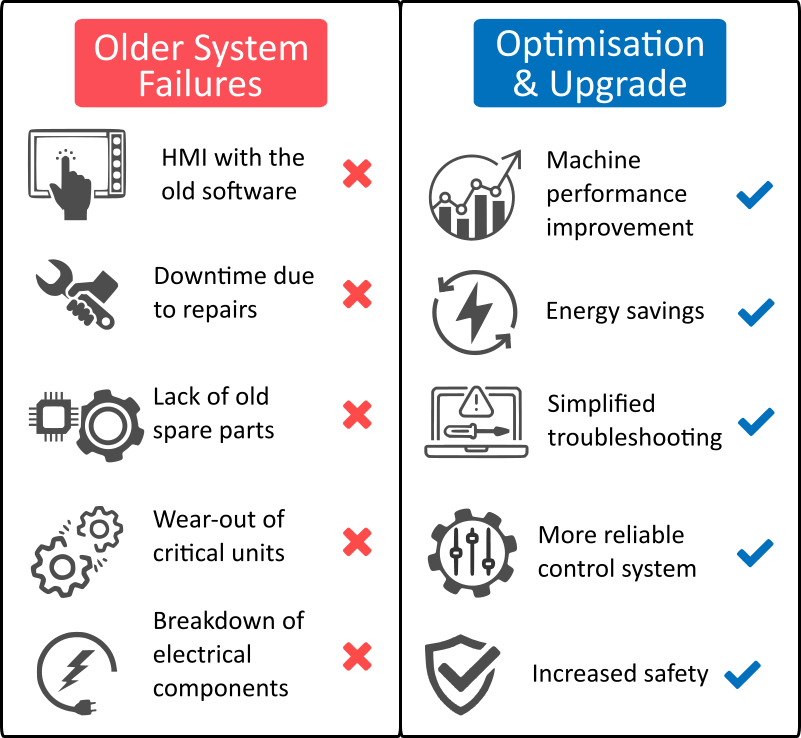

Let our staff evaluate the feasibility and benefits of upgrading your existing automation equipment to improve its effectiveness in your existing packaging solution.

Whether you need to upgrade your automation system or install and start an entire production line, the solutions we provide will be customized to your needs and ensure the best return on your investment.

As an upgrade, we also consider, for example, new product gripping system or a modification of liquid filling nozzles or their increase in quantity.

When developing the design of the equipment and its key components and units, we consider all the product options provided by the client.

The flexibility of our automatic equipment allows to quickly adapt it to new formats of the product or its packaging: new or redesigned ones.

But it is difficult to predict all possible future product modifications. Because of this, our machines are made more modular to make it possible to exchange a separate unit for a new one, designed in accordance with the new product design.

Most of our machines are pre-configured for diagnostics and remote maintenance via the Internet. This guarantees the shortest possible downtime of the equipment and therefore the best possible operational stability of the production.

With the help of the remote connection devices connected to PLC, we can check the current state of the machine to carry out remote diagnosis and remote programming if necessary.

Such remote maintenance saves time and reduces costs. It eliminates preliminary on-site inspection travelling costs by analyzing machine performance remotely and preparing appropriately for a possible intervention on site.

Our after-sales service is at your disposal for all spare parts or troubleshooting requests.

When a problem arises, our service technicians will assist you remotely or on-site.

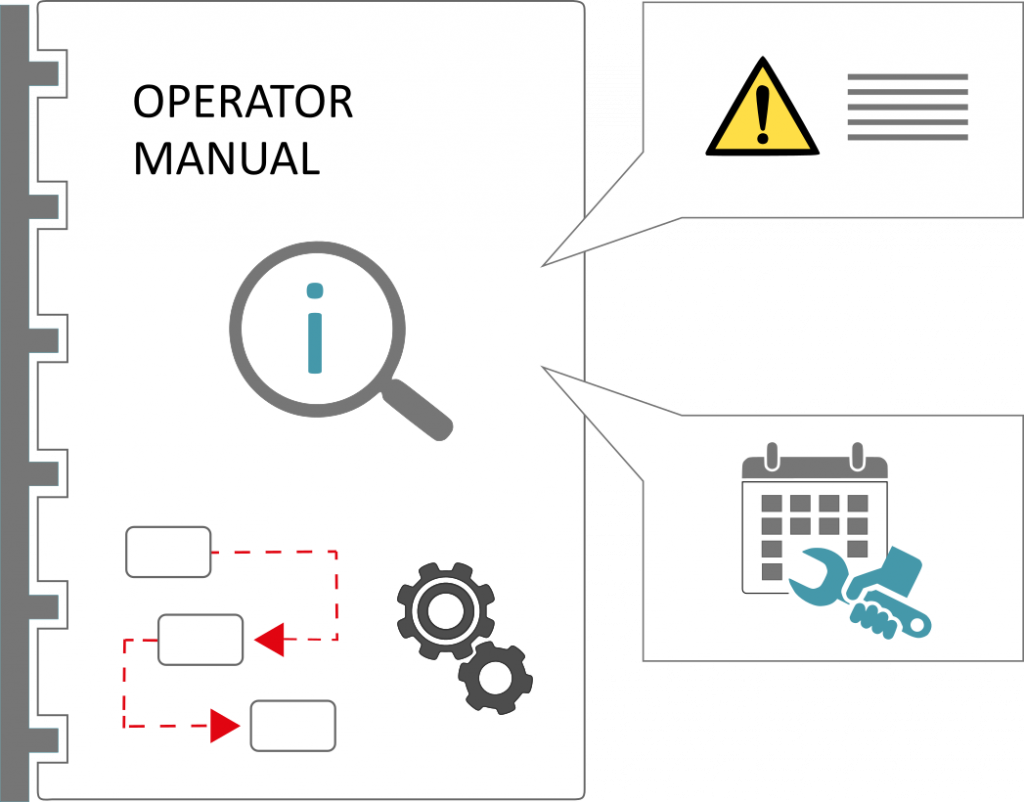

Maintenance schedule can be set up to optimize your equipment – visiting for preventive maintenance operations and replacement of the most wearable (spare) parts.

We provide inspection services to analyze the current condition of the system. We determine the level of service and maintenance needed to ensure high performance and reliability.

Most machine downtime is due to minor issues which can be solved quickly either by phone or by email.

Spare part is a part of a machine which needs replacement more often because of wear and tear. Spare parts play a major role in maintenance of equipment. Without proper replacement of spare parts in time, no equipment can be restored to original condition for proper operation.

After final testing and installation on-site, we will provide you with the list of spare parts needed to be replaced according to a machine maitenance schedule. We keep some spare parts in stock to ensure a fast delivery in the event of a malfunction. Also we have direct contacts with original parts suppliers, so any parts can be rapidly available at the best price.

After final testing and installation on-site, we provide our customers with operator manuals which may include, but is not limited to:

To be able to use your equipment to its maximum capacity, our technicians train your operators after each installation.

After this training, your operators will be familiar with the control system of the machine and all the hardware, will be able to troubleshoot and perform preventative maintenance, and will be aware of all the best practices related to the usage of the machine. In addition, proper training guarantees better safety, improved control of product changeovers, and the optimization of production line settings (mechanical or automated).

Global International has been recognized as a leader in innovative technology solutions for industrial automation equipment as well as conveyor systems, robotic palletizers, case packers, labeling machines, box formers, liquid filling solutions, capping machines, feeding systems, and many others.

We develop robust, flexible, novel solutions from customer specifications to final delivery.

Our automatic equipment is adapted to permanent changes in packaging and product modifications. Our extensive experience can assist you with many engineering challenges you might be facing.

At Global International, our values are the foundation of everything we do. We prioritize integrity, innovation, and customer satisfaction, ensuring that every solution we provide reflects our commitment to excellence and ethical practices.

We believe in the power of collaboration. By working closely with our clients, we develop customized solutions that address their specific needs, fostering a partnership that drives mutual growth and innovation.

Our clients trust Global International for reliable, high-quality solutions. We consistently deliver on our promises, building long-term relationships based on transparency, accountability, and a proven track record of success.

Our focus is on delivering excellence in every project. We remain dedicated to understanding our clients’ goals, ensuring that our solutions are precisely aligned with their operational needs and strategic objectives.

Ready to elevate your operations? Partner with Global International for cutting-edge packaging and automation solutions. Contact us today to discuss how we can help you achieve greater efficiency, reliability, and success in your industry.