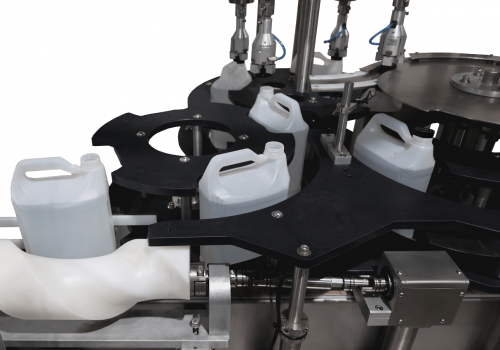

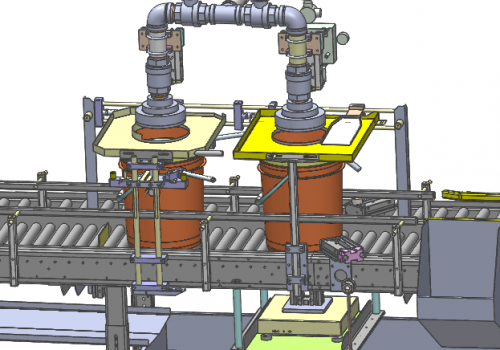

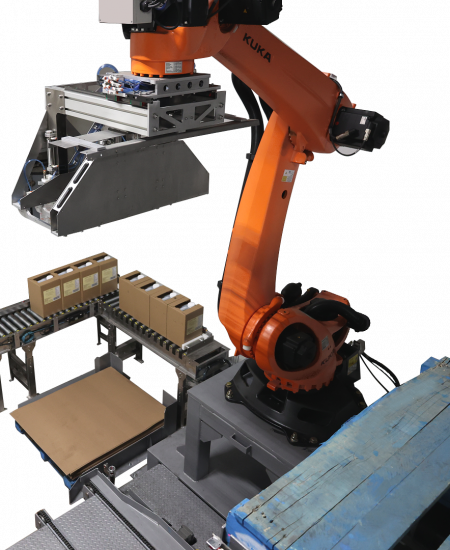

Global International is a proud Canadian trusted industrial equipment supplier, recognized for delivering cutting-edge automation machinery, including robotic palletizers, case packers, labeling machines, box formers, liquid filling machines, capping machines, feeding systems, conveyor systems.

Investing in production automation offers substantial benefits, including increased speed, efficiency, and cost savings. At Global International, we excel in designing and manufacturing customized automatic packaging equipment.

At Global International, our goal is to lead the industry in innovative packaging and automation technologies. We are dedicated to delivering state-of-the-art solutions that enhance efficiency, reliability, and sustainability in industrial operations, ensuring our customers achieve their production goals with precision and confidence.

Global International is committed to incorporating the latest technological innovations into our solutions. We ensure that every product we deliver is equipped with advanced features designed to optimize efficiency and performance.

At Global International, we do our best to make our customers production more reliable and easy to control. With sophisticated by design and technology, our automation systems still have user-friendly features, including HMI touch-screen display with easily configurable and adjustable parameters.

Global International has a long-standing reputation for manufacturing novelty automation equipment. Our team of engineers has decades of experience to craft original and creative engineering technical solutions.

Staying on the Top of Technology reflects our effective implementation of forward thinking strategy. Our company has a vast experience in the creating of robotic automation equipment with fully controllable processes.

Our machinery is engineered for precision and durability, ensuring optimal performance in every application. With cutting-edge technology, we deliver solutions that streamline processes, reduce downtime, and boost overall productivity.

Designed to meet the diverse needs of various industries, our machines offer unmatched reliability. Each unit is rigorously tested to ensure it meets the highest standards, providing long-term value and efficiency.

Our machines are built to excel in demanding industrial environments.

Experience superior quality and performance with our advanced machinery solutions.

Explore our comprehensive range of services, from innovative packaging solutions to advanced automation systems, all tailored to meet the unique needs of your industry.

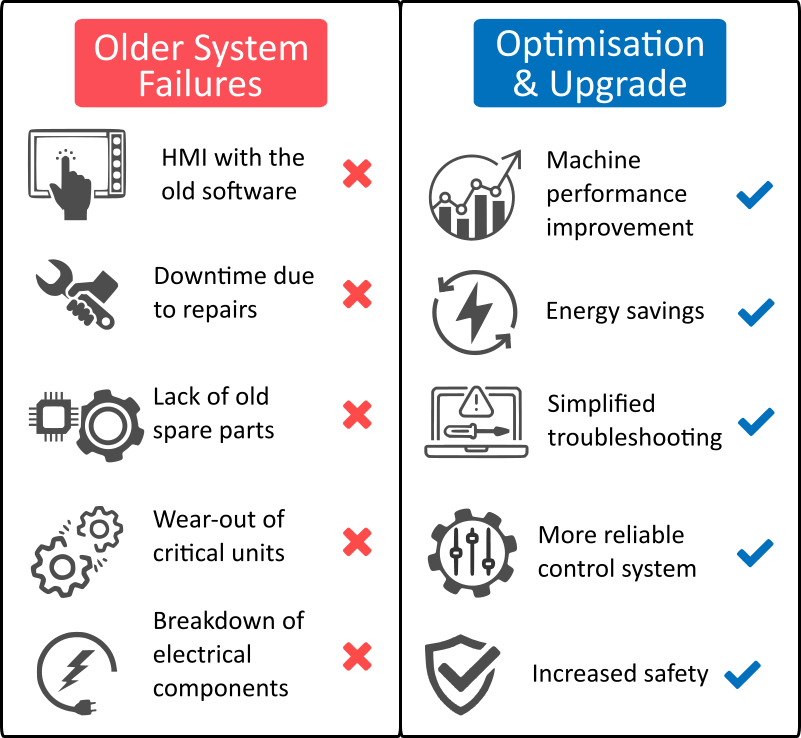

Let our staff evaluate the feasibility and benefits of upgrading your existing automation equipment to improve its effectiveness in your existing packaging solution.

Whether you need to upgrade your automation system or install and start an entire production line, the solutions we provide will be customized to your needs and ensure the best return on your investment.

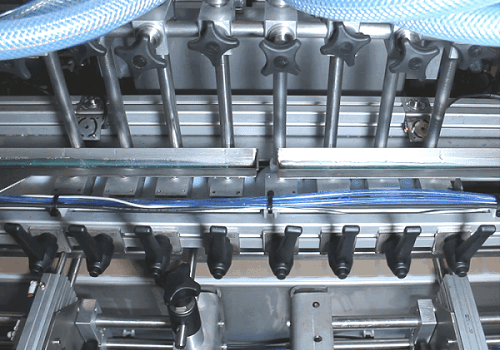

As an upgrade, we also consider, for example, new product gripping system or a modification of liquid filling nozzles or their increase in quantity.

When developing the design of the equipment and its key components and units, we consider all the product options provided by the client.

The flexibility of our automatic equipment allows to quickly adapt it to new formats of the product or its packaging: new or redesigned ones.

But it is difficult to predict all possible future product modifications. Because of this, our machines are made more modular to make it possible to exchange a separate unit for a new one, designed in accordance with the new product design.

Most of our machines are pre-configured for diagnostics and remote maintenance via the Internet. This guarantees the shortest possible downtime of the equipment and therefore the best possible operational stability of the production.

With the help of the remote connection devices connected to PLC, we can check the current state of the machine to carry out remote diagnosis and remote programming if necessary.

Such remote maintenance saves time and reduces costs. It eliminates preliminary on-site inspection travelling costs by analyzing machine performance remotely and preparing appropriately for a possible intervention on site.

Our customers trust Global International for innovative automation solutions. Their feedback highlights our commitment to quality, precision, and reliability, ensuring their production processes run smoothly and efficiently.

Michael Roberts, Operations Director

Sarah Ahmed, Production Manager

Joseph Hyde - CEO of Moiz

Global International has consistently expanded its footprint, establishing a strong presence across multiple industries. Our commitment to innovation and customer satisfaction has driven significant growth and a solid reputation worldwide.

With an ever-growing number of successful projects, we take pride in our global reach and extensive industry expertise. Our dedicated teams operate from multiple offices, ensuring we cater to a diverse range of clients across various sectors. Our achievements reflect our relentless pursuit of excellence, making us a trusted partner in the packaging and automation industry.

At Global International, our team is our greatest asset. Comprising seasoned experts in automation and packaging technologies, each member brings a wealth of knowledge, innovation, and dedication to their role. Our collaborative approach ensures that we deliver top-tier solutions tailored to your needs. Meet the talented individuals driving our success and commitment to excellence.

Ready to elevate your operations? Partner with Global International for cutting-edge packaging and automation solutions. Contact us today to discuss how we can help you achieve greater efficiency, reliability, and success in your industry.